Research & Development

Cutting-Edge R&D Expertise in High-Performance Microphones and Headphones

In our relentless pursuit of producing high-quality microphones and headphones, YOGADA's engineering team continuously explores new materials and adopts diverse and effective solutions during the early stages of the design process. Our commitment to staying abreast of market trends ensures we meet the growing demands for high-performance microphones and headphones featuring environmental noise cancellation and voice activation.

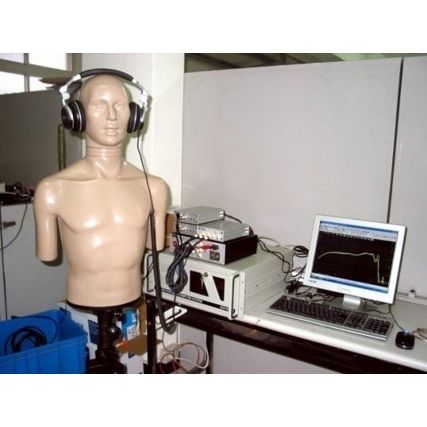

Professional-Art Testing and Analysis Equipment

YOGADA leverages advanced equipment such as the B & K audio analyzer, CLIO IEA Electro-Acoustic system, and an anechoic chamber room to ensure consistent acoustic performance across our future productions. This ensures that every high-quality microphone and headphone we produce meets rigorous performance standards and exceeds customer expectations.

Expertise in Development and Manufacturing

With a knowledgeable development team and a skillful manufacturing facility, YOGADA offers competitive and quality products to customers worldwide. As a professional OEM & ODM factory, our expertise in the production of high-performance microphones and headphones ensures that we can provide tailored solutions that cater to a wide range of customer requirements.

Commitment to Innovation and Quality

Our dedication to continuous improvement and technological advancement drives us to explore new frontiers in audio engineering. By professional technology and maintaining stringent quality control processes, we deliver products that not only meet but exceed industry standards.

YOGADA is a professional OEM & ODM factory that meets your demands for high-quality microphones and headphones. Our expert team will provide you through every step, ensuring your vision becomes a reality. Besides, we have a one-stop service from start to finish for clients. We have an engineering team located in Taiwan with experience to support the projects. Contact us today to learn more about our advanced R&D capabilities and how we can support your product development goals.

Development Process

- Market Research: Conducting thorough research to understand market trends and customer needs.

- Product Proposals: Developing tailored product proposals based on market insights and client requirements.

- Concept Designs: Creating innovative and functional design concepts for new products.

- Circuit Designs: Designing and optimizing circuit schematics for enhanced product performance.

- Mechanical Files: Detailed mechanical drawings and specifications for manufacturing.

- Prototyping and Verification: Building and testing prototypes to meet design specifications and performance standards.

- Open Tools: Utilizing advanced tools and technologies to refine and develop product designs.

- Pilot Run(Trial run): Running initial production trials to validate processes and product quality before full-scale manufacturing.

- Mass Production(MP): Scaling up production to meet market demands with consistent quality and efficiency.

- Certifications: Securing relevant certifications to ensure products meet industry standards and regulatory requirements.

more photos

- The KEMAR MANIKIN Acoustic Analyzer, every Microphones and Headphones orders will doing inspection through analyzer before the shipment.